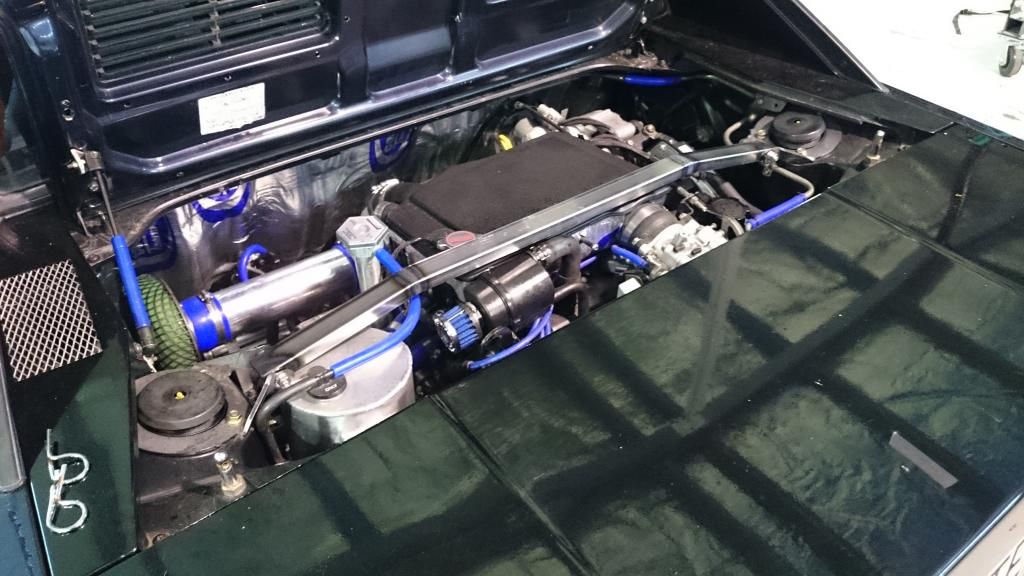

The reason a standard lid's vents face forwards is because the air is traveling forwards across the engine lid, and yes those vents are exhausts, not intakes.

As for the standard spoiler, it isn't even in the airflow at 100kmh as my tell-tale tests showed years back.

The way the standard spoiler (very slightly) helps decrease the drag is by assisting the vortex that is happening over the engine lid.

Air flows off the roof, but swirls down near the rear wing, flows forwards along the engine lid, and back up at the rear window. This air is reasonably slow moving and is referred to as a "separation bubble". This slow moving bubble of air acts as if the car had a gently sloping rear roof allowing the laminar layer to flow nicely rearwards, some distance above the engine lid and boot lid.

The separation bubble also helps generate higher pressure around the back of the car as compared to what there would be without it. Shear vortices are detached some distance behind the separation bubble too, thereby further reducing drag. The same thing reduces drag in a ute with its rear door up and no tray cover with an empty tray, as (not very scientifically) demonstrated by Mythbusters.

If you Google about separation bubbles and aero you'll see what I mean.

If you look at the tell-tales in my test shot you'll see the laminar flow above 15cm and the rear edge of the separation bubble is causing the tell-tales below 15cm to drop lazily down. In fact you can even see the very bottom tell-tales are being gently sucked forwards.

I once left a jersey on the engine lid and some kilometres later noticed it in my rear view mirror, snuggled up against the rear window.

Here's a separation bubble showing the direction of its flow, as featured in a scientific aero discussion:

And here's my depiction of the aero on an AW. Green is separation bubble flow (slow moving), pink is engine air flow, brown is laminar flow of the air as it hurtles past the car.

Basically if you wanted to assist your aero you would vent your engine bay forwards and upwards near the rear window, and if anything fit an almost vertical spoiler on the rear edge of the boot, perhaps 15cm tall. Because my tests showed that the laminar flow misses the top of the rear edge of the boot by about 15cm at 100kmh, therefore a spoiler to that height would assist in maintaining the separation bubble.

If you leave your engine vent at the rear edge of the boot I suggest you add a near-vertical spoiler above it to prevent your engine vent from destroying the separation bubble (and thereby increasing drag).

Anyway that's my amateur 5 cents' worth Malcolm.