More updates:

I've nearly finished the engine lid. Following on from the last post, I finished the framing on the mould so it would bolt to the hinges to help locate everything:

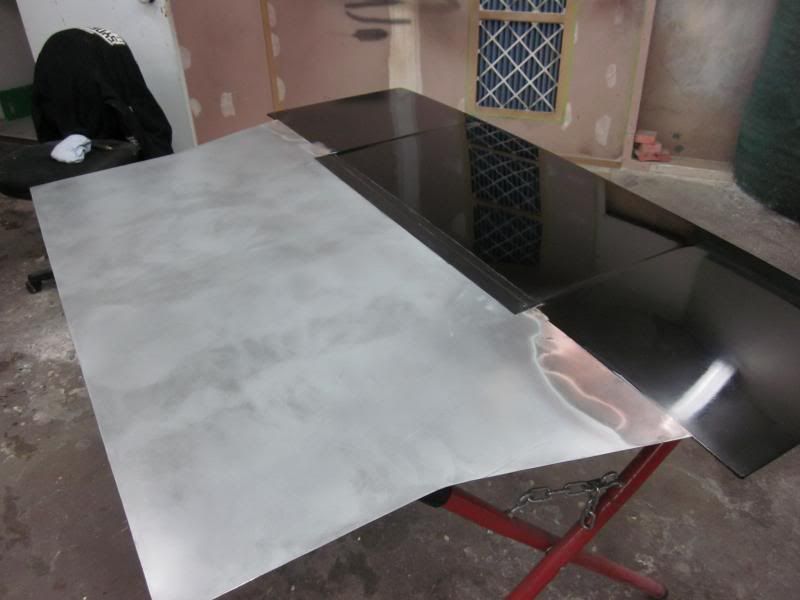

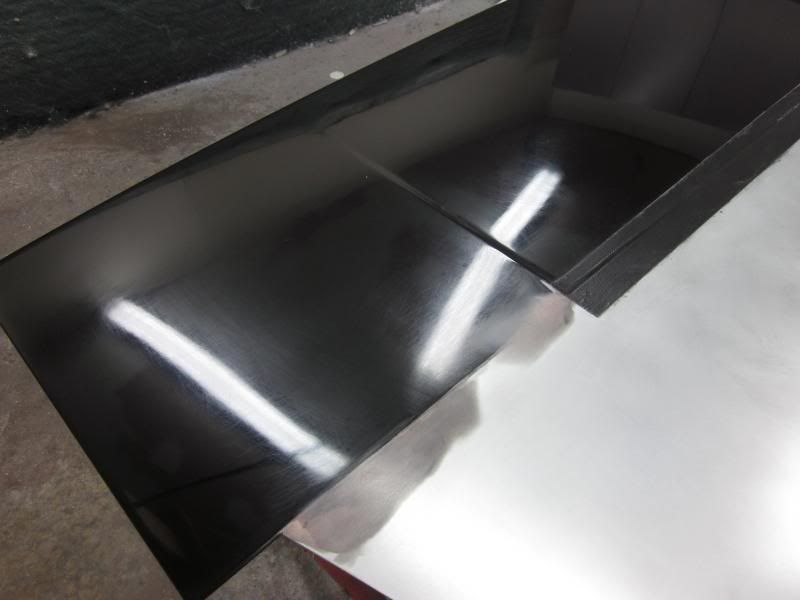

I then put the steel sheet on to finish off the top side, smoothed out the join with body filler and polished & waxed it

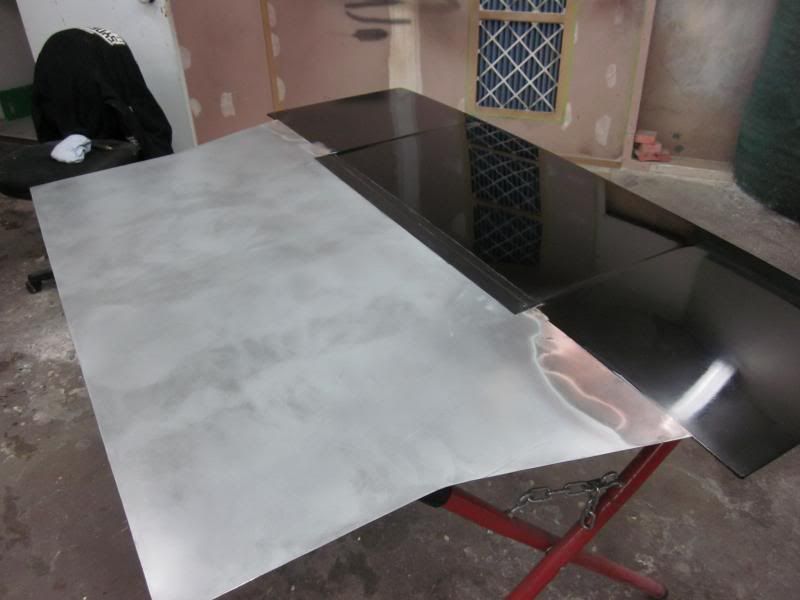

I wasn't sure how well the fibreglass would release from the unpainted steel, but decided it would probably be ok with wax, given it's not a porous surface. I didn't take too many pics of the layup process, but I did it a fairly unusual way. First I laid up skin of two layers of 200gsm woven glass. Each layer was a single, continuous piece of cloth so there would be no variation in thickness. Finally I covered it in peel-ply to give it a flatter surface. This picture shows how floppy this skin turned out - kinda like a laminated poster or something.

Next step was to remove this skin from the mould (thankfully it released very easily), then lay down another skin just the same with 2 layers of cloth. This time however, after laying down the cloth I added a layer of 3mm foam core while the resin was still wet.

Then, while the resin was still wet I painted more resin onto the foam core and then put the first (already cured) skin on top. This came out really well and allowed me to make a nice, stiff but lightweight piece straight off a male mould/plug without having to make a complete female mould. It doesn't look like I've taken a good picture of the lid at this stage.

Next step was to make the hinge mounts. I found some suitable aluminium box section and put some stainless rivnuts in it

Cut the piece into two and bolted them to the hinges

Put some Plexus glue on the top face

Then I sat the lid into place and let the glue cure. Here's the lid being held up quite happily but the little twos'r'us gas strut. You can also see the green foam I've attached to make the sealing surface for the boot. I don't have a picture but I've also attached the boot catch to hold it down, using the same method as I did for the hinge mounts

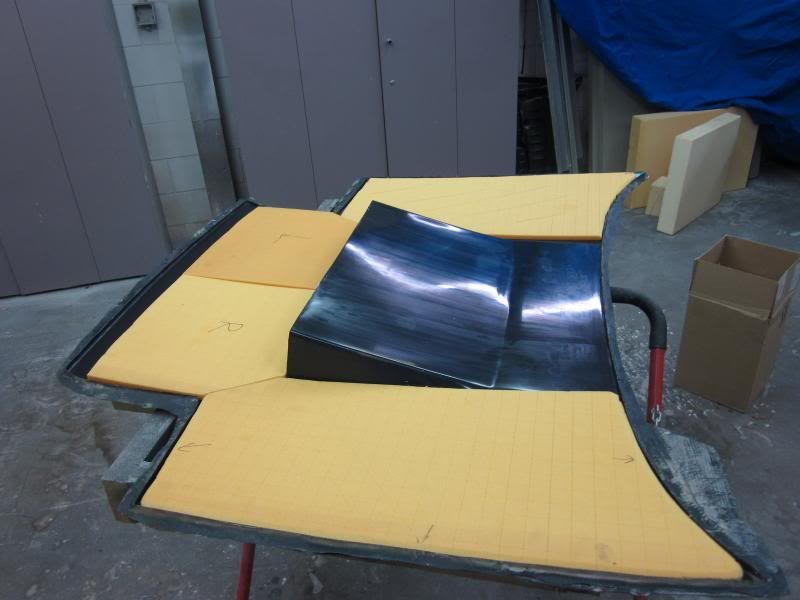

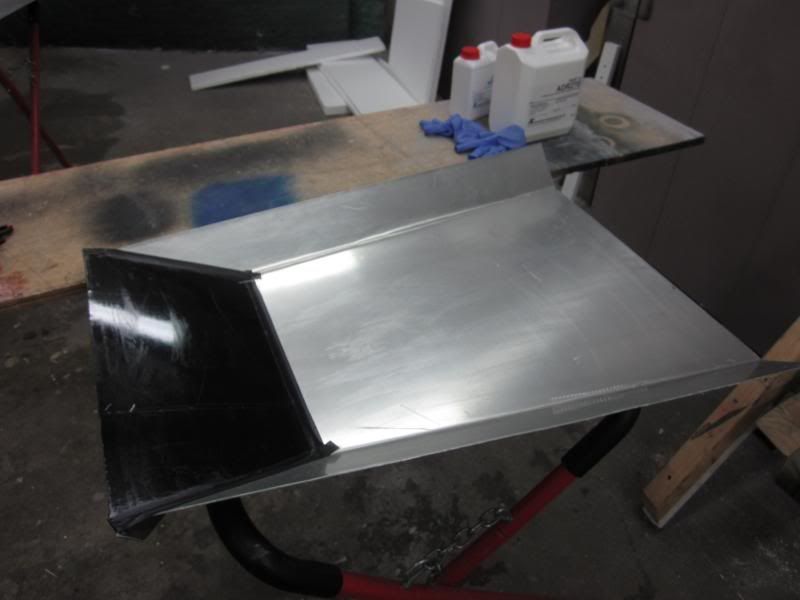

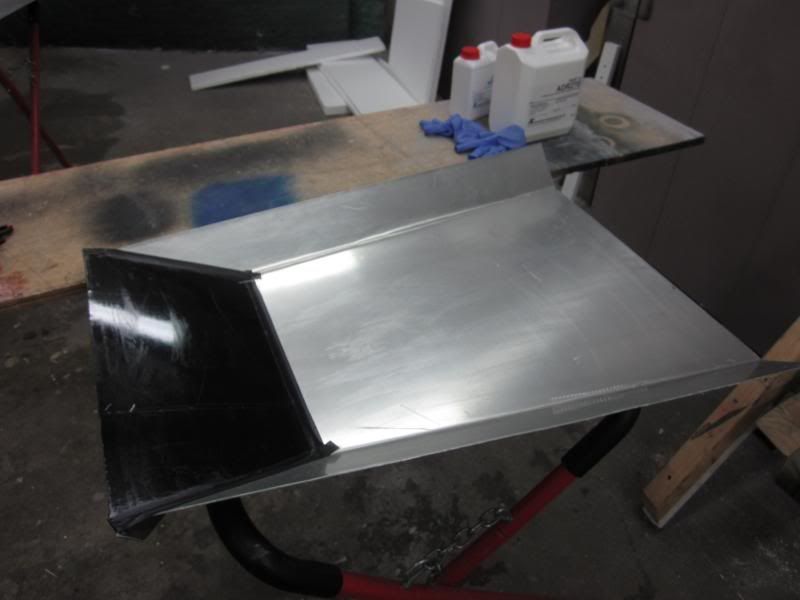

So the other part of this engine lid is the vent. I half made a mould for this using some aluminium sheet a few years ago. I finished that off and modified it slightly with the black plastic sheet you can see in this picture

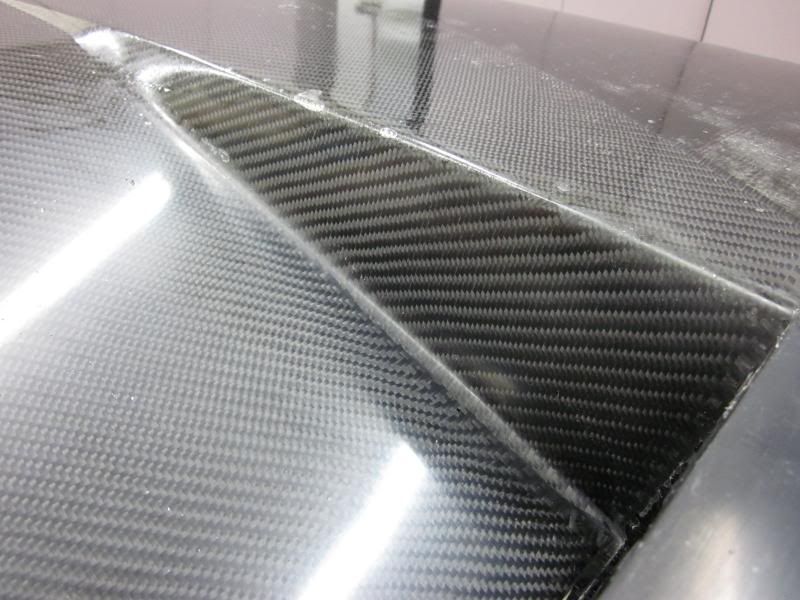

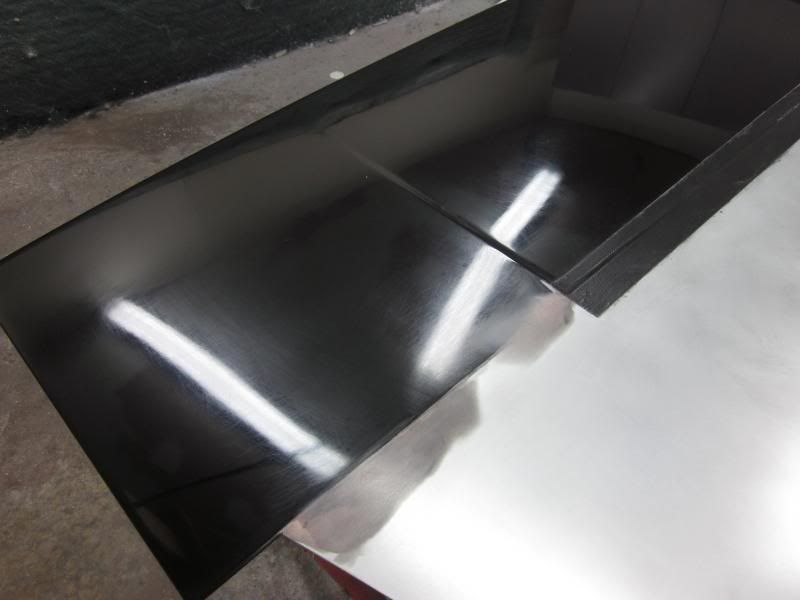

I laid this up with two layers of 200gsm cloth, then some 3mm core, then another two layers of cloth. I forgot to pigment the resin on this, so it's translucent and you can clearly see where I've placed the core. I went back and added some core on the sides too because they were too floppy.

Some pics of the vent test fitted on the lid

Since those pics I've trimmed it a little so it's about 3/4 of the height that it is here. I just need to finish trimming it up to make sure it's symmetric and then I'll laminate it to the engine lid. Pretty stoked with how it's gone so far - as always more work than I expected but it's getting there. I think the finished weight will be around 3.5-4kg, which along with the removal of one latch and one set of hinges could be a weight saving of around 10-12kg I think.